Partner for the highest standards.

Our quality standards start right at the beginning of the supply chain: we know our suppliers personally and carry out regular inspections of their production facilities. This enables us to ensure that respectful and legally compliant treatment of people, nature and the environment is guaranteed at all times.

Our own brand products - IBC SOLAR quality innovations.

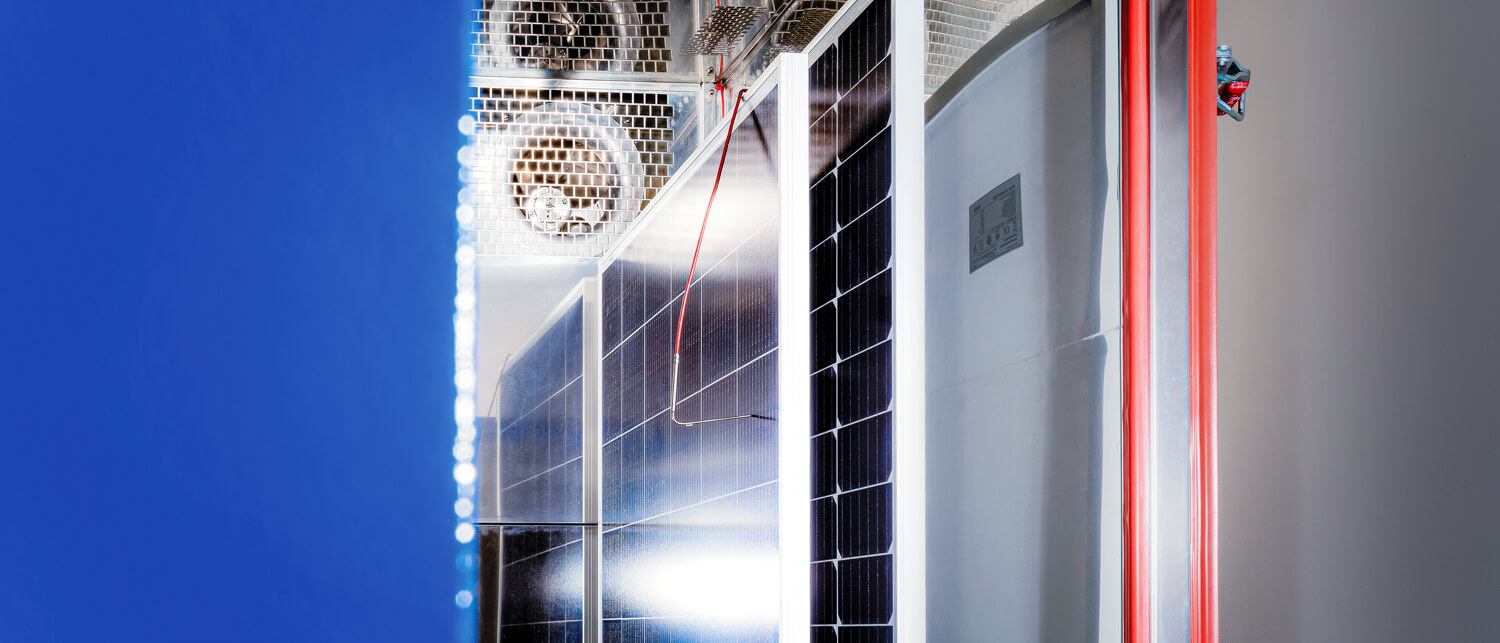

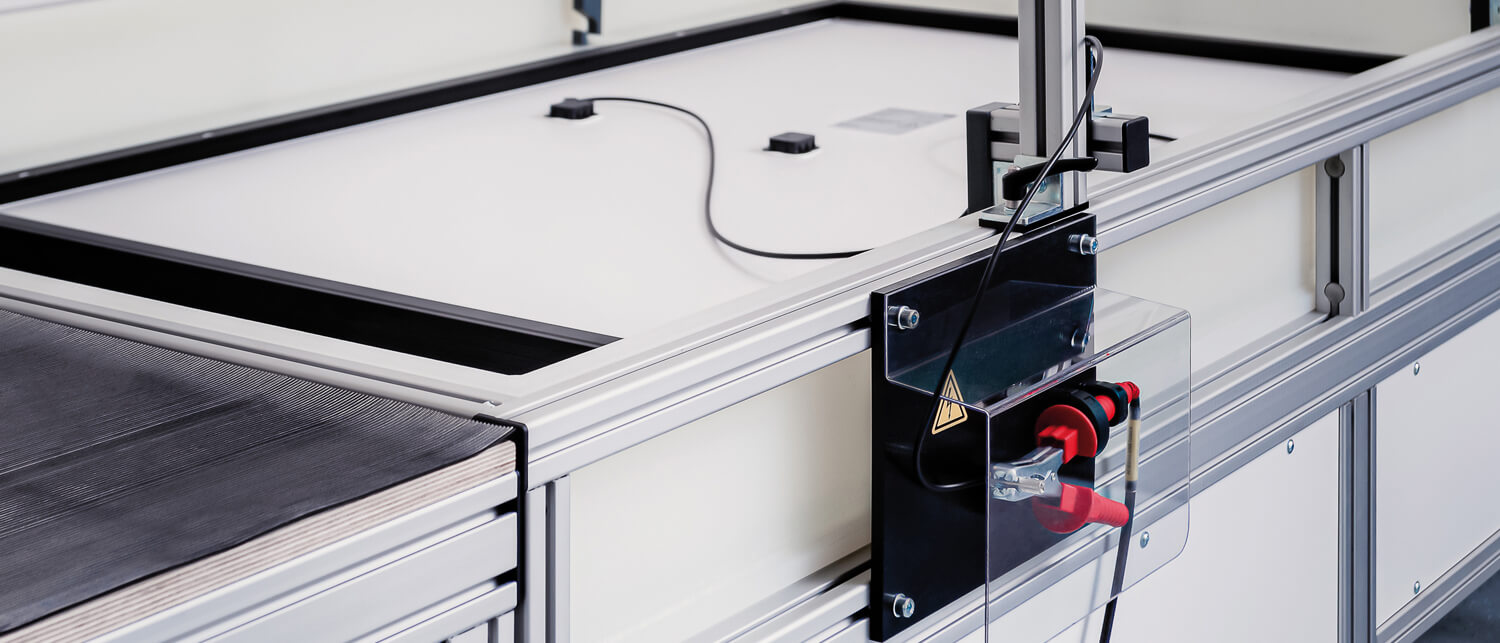

One thing that sets IBC SOLAR apart is that we don’t just install components by renowned, certified manufacturers — we also develop our own high-performance solutions for everything from modules to storage. IBC SOLAR modules and bracket systems are tested separately and together for bending and breaking at SUNLAB’s independent PV testing laboratory. It’s the only quality assurance measure of its kind in the industry.

Tested and certified quality.

Our products are certified according to currently valid standards and inspected by globally recognised institutions such as the TÜV, the VDE, and Fraunhofer ISE. Extensive incoming goods inspections and long-term tests under real-world conditions in our testing facility system help us maintain consistently high standards of quality.

Reliability throughout the life of the system.

Since we are confident in the quality of our products and appreciate the importance of reliability and trust, we offer our customers longer-than-average warranties and comprehensive insurance policies. This means that you can enjoy the use of your solar system for its entire service life without any worries, and when the system really has reached the end of its service life or modules need to be replaced, we work together with the waste disposal company Take-e-way in Germany, for example, which takes care of proper recycling and recycles up to 95% of solar systems.

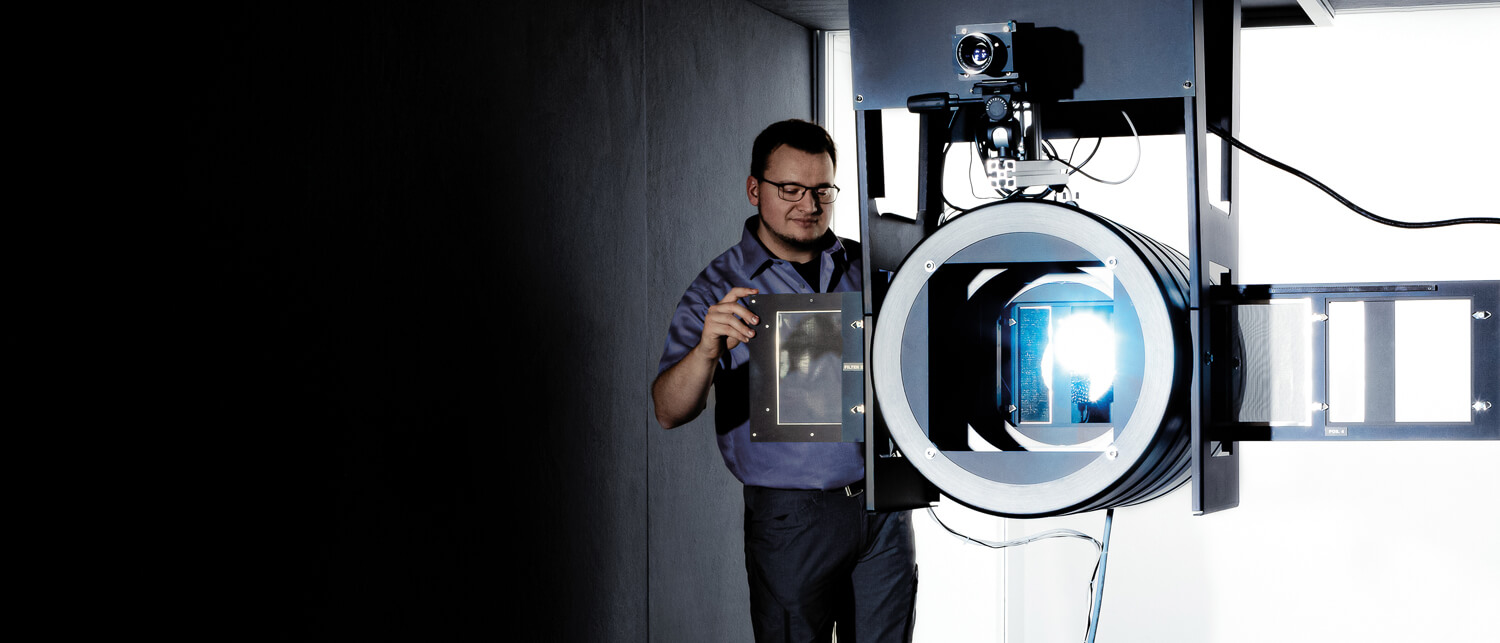

How SUNLAB tests.

SUNLAB’s independent, autonomous testing laboratory is run by solar experts with many years of experience testing photovoltaic modules and components. It uses professional, standardised testing procedures in its high-tech machine and laboratory park, ensuring objective results that reliably identify potential weak points and offer a clear picture of the tested module’s quality and performance.

PV modules run a 7-test gauntlet at SUNLAB.

SUNLAB

Would you like to find out more about SUNLAB, its services and the team behind it?

Go directly to SUNLAB here

ISO certification by TÜV Rheinland

TÜV Rheinland has given us official confirmation of the company philosophy and quality guarantee we have always practised. Since June of 2012, IBC SOLAR AG has been certified according to:

- DIN EN ISO 9001 for quality management

- DIN EN ISO 14001 for environmental management

- DIN EN ISO 45001 for occupational health and safety

Our growing Technical Management and Maintenance (O&M) business segment also numbers among our ISO-certified processes. Many of our products are also subject to TÜV Rheinland inspections and hold ISO certification.

View IBC SOLAR’s ISO certificates here

Info about our long-term guarantees

Product

Product and service guarantees

IBC SOLAR’s product and service guarantees reflect the high standards to which we hold ourselves as a German guarantor. Our quality-assurance system is unparalleled in the industry, with everything from supplier qualifications to the seven robustness tests we commission from the SUNLAB PV testing laboratory. This helps ensure that our modules deliver on our promises and offer maximum energy yields at all times.

Product combinations

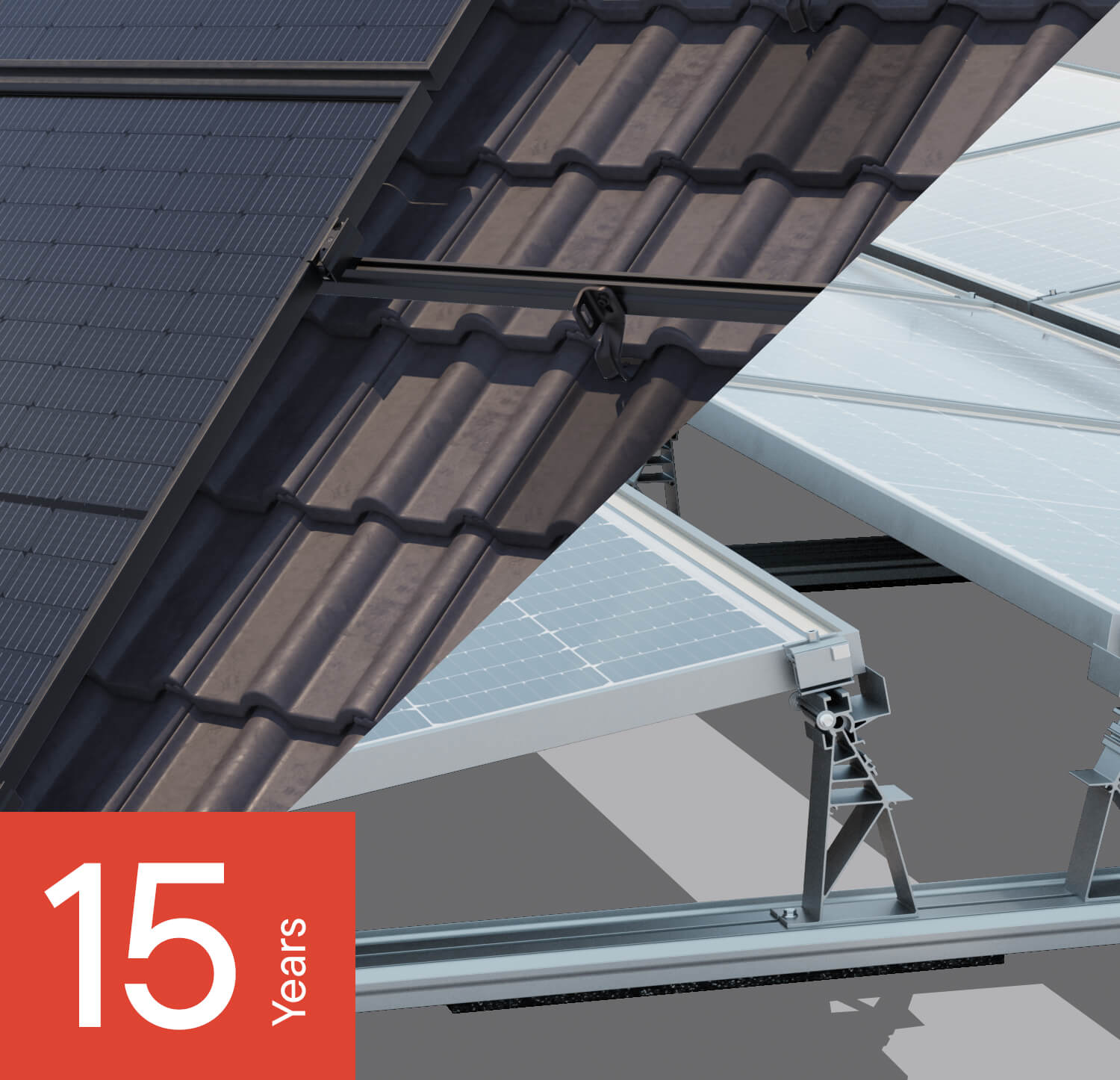

Our 15 years mounting / module combo warranty

We don’t just test our modules by themselves—we apply the same rigorous standards to module-and-bracket combinations. How else could we offer you such outstanding warranty promises? This combination warranty also applies to any consequential damage that occurs to the connection between IBC SOLAR brackets and modules. It’s all straightforward and completely free of charge to you for the next 15 years.